What is an antimicrobial masterbatch?

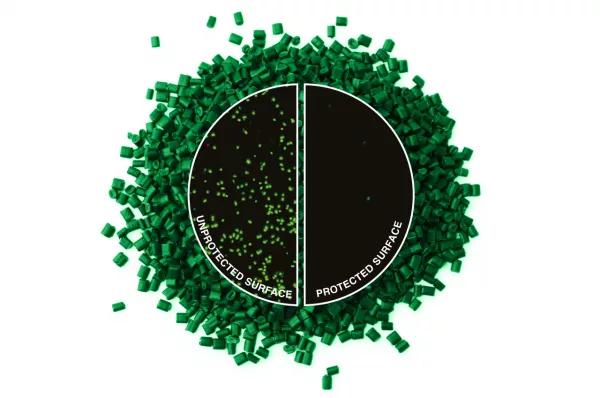

Antimicrobial additives are incorporated into carrier resin pellets to create an antimicrobial masterbatch. It is used during plastic processing, providing the finished product with lasting surface protection against microbes such as bacteria, mold, and mildew.

An antimicrobial masterbatch is supplied in carriers suitable for most polymers, including PVC, PE, HDPE, PP, polyamide, polyester, ABS, polycarbonate, and styrenics.

Why use antimicrobial masterbatch in plastic manufacturing?

There are several compelling reasons plastic manufacturers are increasingly adopting antimicrobial masterbatch:

Extended product lifespan: Plastic products that inhibit microbial growth are less prone to premature deterioration caused by bacteria buildup, mold, or mildew.

Enhanced surface cleanliness: For applications where product cleanliness is critical, antimicrobial plastics complement existing cleaning routines by preventing microbial buildup and staying cleaner for longer between cleans.

Added value for customers: Helps deliver added peace of mind

What is antimicrobial masterbatch used for?

Antimicrobial masterbatch is ideal for any plastic product that either:

Is susceptible to microbial growth due to frequent contact with moisture or organic material

Has a long service life

Is difficult to clean, such as large equipment or hard-to-reach applications

Operates in challenging environments where mold, bacteria, and mildew thrive

Typical applications that benefit from antimicrobial masterbatch:

Cutting boards

Food storage containers and plastic food service items

Sealants and gaskets

Medical and healthcare devices

Automotive interiors

Water tanks and pipes

Shower curtain liners

Building materials